Precision in luxury vehicle repair, especially for Mercedes, revolves around meticulous gap measurement. This involves detailed assessments of bodywork clearances, documented with visual and laser scans to ensure structural integrity, safe driving, and warranty compliance. Skilled auto body shops follow a step-by-step process, cleaning, repairing, and consistently documenting measurements to maintain legal and consumer rights, preventing voided warranties and disputes.

Mercedes owners expect nothing but precision from their vehicles, and proper Mercedes gap measurement is crucial for both performance and warranty compliance. This comprehensive guide delves into the essential practices for documenting gap measurements, ensuring accuracy is maintained throughout the process. From understanding Mercedes’ specific requirements to step-by-step documentation and strategies for upholding warranty claims, this article equips you with the knowledge to maintain your Mercedes to factory standards.

- Understanding Mercedes Gap Measurement Requirements

- Documenting the Process Step-by-Step

- Ensuring Accuracy & Compliance for Warranty Claims

Understanding Mercedes Gap Measurement Requirements

In the realm of luxury vehicle repair, especially with brands like Mercedes, precision and adherence to specifications are paramount. Mercedes gap measurement refers to the meticulous process of assessing and documenting the clearances between various components of a vehicle’s bodywork. This isn’t merely about ensuring the car looks good; it’s about maintaining structural integrity, facilitating safe driving, and complying with warranty requirements. Every detail, from panel gaps to alignment specs, must meet stringent standards set by Mercedes-Benz.

Automotive repair professionals play a crucial role in this process, as they are responsible for accurately documenting Mercedes gap measurements during service or repairs. These records not only help in achieving flawless vehicle bodywork but also serve as vital compliance documents. For luxury vehicles like Mercedes, where quality and precision are hallmarks of the brand, meticulous gap measurement and detailed record-keeping ensure that each repair or modification adheres to original equipment manufacturer (OEM) specifications, thereby safeguarding both consumer satisfaction and legal compliance.

Documenting the Process Step-by-Step

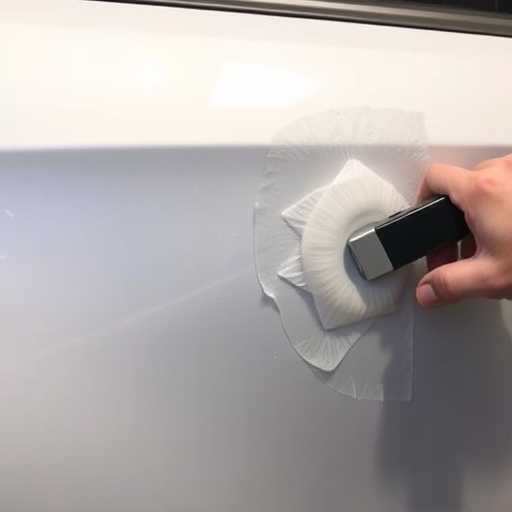

Documenting the process step-by-step is crucial for maintaining accurate Mercedes gap measurement records. The first step involves inspecting the vehicle thoroughly to identify any existing gaps or damages, using both visual assessment and specialized tools like laser scanners for precise measurements. Once identified, each dent or gap should be meticulously recorded with detailed descriptions, including size, depth, and location.

Next, the preparation phase begins, where the area around the damage is cleaned and degreased to ensure proper adhesion during repair. Following this, the actual car paint repair or dent removal process takes place, utilizing techniques specific to Mercedes vehicles. Auto body shops skilled in these methods will employ a combination of manual labor and advanced equipment to restore the vehicle’s original condition. Throughout each step, consistent documentation is key, updating records with progress notes and final measurements to ensure compliance and facilitate future reference.

Ensuring Accuracy & Compliance for Warranty Claims

Maintaining precise Mercedes gap measurement records is paramount for both warranty claims and compliance purposes. Accurate measurements ensure that repairs align with manufacturer standards, protecting consumers from substandard work and potential future issues. When a vehicle undergoes body repair, including scenarios like car scratch repair or even more complex vehicle collision repair, documenting each step meticulously becomes crucial. This includes measuring the gap between various components to guarantee their proper alignment and functionality after the fix.

Non-compliance can lead to voided warranties and legal ramifications, making it essential for workshops handling Mercedes vehicles to adhere strictly to measurement protocols. By keeping detailed records, mechanics can prove the integrity of their work should a dispute arise regarding warranty coverage. This transparency benefits both parties, ensuring customer satisfaction while also facilitating efficient claims processing.

Mercedes gap measurement documentation is a crucial aspect of maintaining compliance and ensuring warranty claims are processed smoothly. By understanding the specific requirements, accurately documenting each step, and prioritizing precision, automotive professionals can effectively manage Mercedes-Benz models’ unique gaps, thereby enhancing customer satisfaction and streamlining after-sales service processes. This meticulous approach to Mercedes gap measurement standards is vital for keeping records in check and upholding the brand’s high-quality reputation.